John Oxley Restoration

Update July 2010

SUPPORTING THE PROJECT

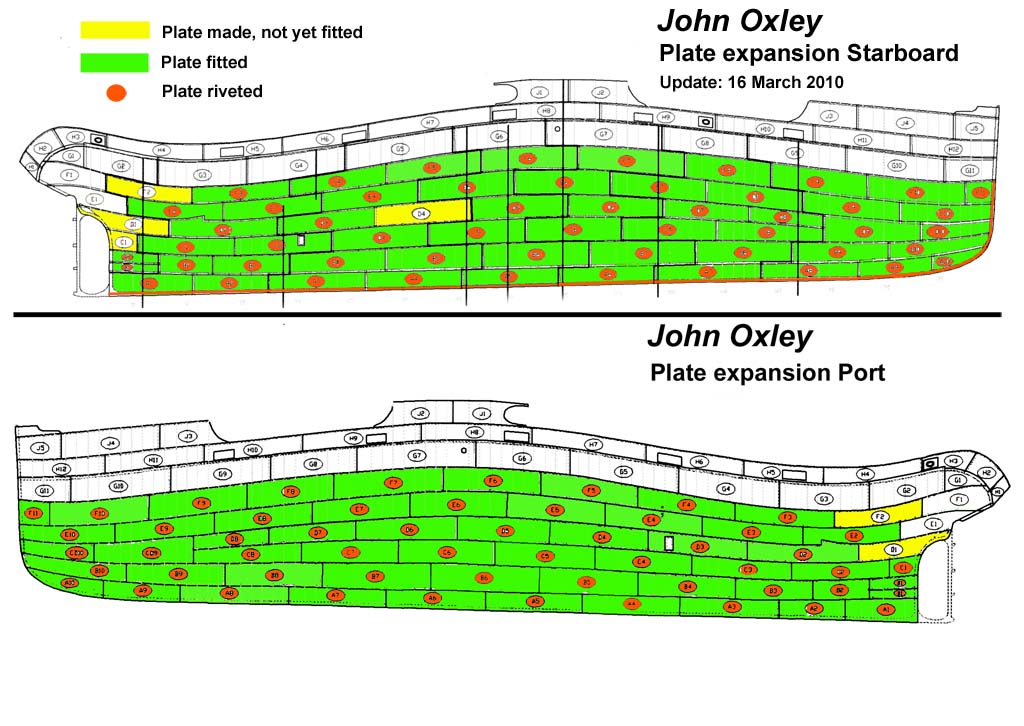

We have advanced to the stage where we can say “24 Hull plates to go!“. These are all above the waterline and mainly consist of the sheer strake plates and the stern counter. And we are only at this stage because of our dedicated volunteer workforce and our supporters. Your continuing support of this remarkable project continues, thanks.

HULL

Plating – Recent milestones include the completion of hull plating up to the sheer strake. Seen here is riveter Onzie driving home the last rivets to close up this part of the hull.

Plating – Recent milestones include the completion of hull plating up to the sheer strake. Seen here is riveter Onzie driving home the last rivets to close up this part of the hull.

All bottom plates entail overhead riveting, which is recognised as being particularly arduous.

This is a real achievement, it means that the port and starboard hull are now plated up to just above the water line. One engine room plate is made but left off to allow the engineers easier access to their realm. It will be fitted shortly before refloat.

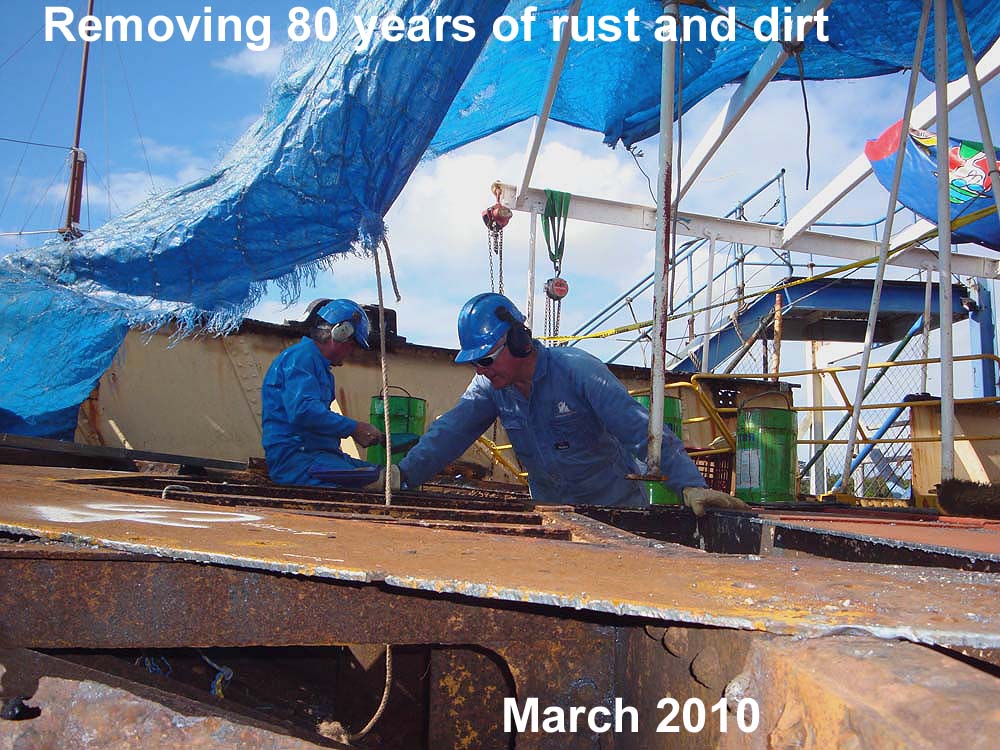

Stern counter – Work has now shifted to the stern counter structure and plate work. Work from early 2010 included removal of the teak deck followed by lifting of steel deck and margin plates.

The expected rust and wastage are present. Surprisingly, the steel plates beneath the teak decking were in good condition, so good in fact, that it is only necessary to replace sections of the outer or margin plates in the gutter area.

The expected rust and wastage are present. Surprisingly, the steel plates beneath the teak decking were in good condition, so good in fact, that it is only necessary to replace sections of the outer or margin plates in the gutter area.

The gutter was lined with concrete between an inner angle riveted to the deck plate and the outer angle. The outer angle is flared out to match the angle of the sheer strake and the bulwark. It forms the connection between these plates and the margin plate. The angles are curved and need to be shaped in the workshop to match the outline of the ship’s deck.

Bulwark – Bulwarks aft starboard side were released when the stern counter plates were removed. These plates show some rust, some are new steel plates from the 1980’s periods, and some good steel. They were removed to the workshop for repair.

The bulwark aft is very complex as it flares out towards the top. In essence it forms a section of an inverted spiral cone. The top and bottom need to meet a plane. A special bending rig was constructed to gradual bend the plate till it had the right shape. The combing needs to follow the same curve. They are shaped using a similar method as for the hull frames using heat from a oxy-torch and bending it around dogs on the engineering table.

essence it forms a section of an inverted spiral cone. The top and bottom need to meet a plane. A special bending rig was constructed to gradual bend the plate till it had the right shape. The combing needs to follow the same curve. They are shaped using a similar method as for the hull frames using heat from a oxy-torch and bending it around dogs on the engineering table.

Counter plating – The complexity and shaping of the stern components make for relative slow progress compared to straightforward hull plates. At this point about half the stern plates and frames have been made.

The counter plates are of a complex shape and have a knuckle to join the deck angle and the bulwark. Careful measurements were made of the old plate and the knuckle was bent in sections with slits in the plate between them. The slits will be welded when the fitting is complete. The knuckle angle varies over its length. It is sheer engineering artistry.

Rudder trunk – A new rudder trunk has been made to replace the old one. It was made from a length of pipe. Slits were cut in the wall and the pipe squeezed together to approximate the cone shape of the original. It is now riveted onto place.

Scaffold – These views also show the loaned scaffolding used by the project. When the height of the work exceeds 4 metres, a engineered scaffold system must be installed by a licensed scaffolder (long term member Stuart Harvey) and signed off by a registered scaffold inspector. We thank Kell & Rigby for their long term support here.

ENGINEERING

Condenser shell – The condenser has been raised about 20 mm. in preparation for repairs to the shell where it rests on its supports. The shell is rusted through here and welded repairs are necessary. When complete, the condenser can be lowered back down. This will enable the circulating pump, associated piping and sea valve to be fitted.

Condenser shell – The condenser has been raised about 20 mm. in preparation for repairs to the shell where it rests on its supports. The shell is rusted through here and welded repairs are necessary. When complete, the condenser can be lowered back down. This will enable the circulating pump, associated piping and sea valve to be fitted.

Treadplates – With hull plate and structural repairs in the engine room completed, the engine room treadplates and supports are going back in. This will enable safe working platforms in the engine room to be re-established.

Treadplates – With hull plate and structural repairs in the engine room completed, the engine room treadplates and supports are going back in. This will enable safe working platforms in the engine room to be re-established.

Weir main feed pumps – Overhaul of these two important pumps is nearly complete. This has been a long term project and has seen steam and pump cylinders re-bored and honed, new steam and water piston and ring sets made and the famous Weir shuttle valve chests overhauled.

These pumps will be test run on compressed air and then broken down into sub-assemblies for return to the ship.

Ballast pump – The last auxiliary from the engine room to be restored ashore is the Dawson & Downie ballast pump. This pump is the largest steam duplex pump in the Heritage Fleet and has been progressively worked on since its removal from the ship some years ago. The pump end was chemically treated to stabilise rust and then hydraulic tested.

Ballast pump – The last auxiliary from the engine room to be restored ashore is the Dawson & Downie ballast pump. This pump is the largest steam duplex pump in the Heritage Fleet and has been progressively worked on since its removal from the ship some years ago. The pump end was chemically treated to stabilise rust and then hydraulic tested.

VOLUNTEER WORKFORCE – WE NEED YOU!

WE ARE NEEDING

As the hull approaches refloat, additional resourcing is needed.

Can you help fundraise? Contact our office on (02) 9298 3888.

Support from business or industry? Are you able to provide steel, tools, fastenings, or products and services to the project? See Wish List below.

| ▪ | Publicity / promotions – volunteers to help with website, email, reports |

| ▪ | Events – planners and promoters – events for members, sponsors |

| ▪ | Merchandising – apparel, souvenirs and publications – shop counter and on-line |

Can you help? Contact us on (02) 9298 3888 or drop in to the Heritage Shipyard.

WE ALSO NEED…

| ▪ | Carpenters and shipwrights – on deck |

| ▪ | Fitters / machinists / engineers / machinery restorers |

| ▪ | Fabricators / riveters / iron workers – in workshop and on board |

| ▪ | Painters – everywhere… |

Contact us on (02) 298 3888 or drop in on the project and ask to see Tim Drinkwater or one of the John Oxley team.

WISH LIST

| ▪ | Plasma cutter |

| ▪ | Nuts and bolts, especially the larger Whitworth sizes |

| ▪ | Oxy-acetylene cutting equipment – new gauges and flashback arresters |

| ▪ | Riveting tools – especially old style … getting very scarce… |

| ▪ | Air tools, power chisels, needle guns… |

| ▪ | Electrical tools, drills, grinders… |

| ▪ | 3MT drill press |

| ▪ | Blacksmithing tools – ramping up our smithy |

| ▪ | Horizontal borer – we bore out a lot of cylinders – not too large… |

FAMOUS STEAMSHIPS STILL IN STEAM!

SY Delphine is no utilitarian coastal steamship, but she is certainly evocative of the great age of steam. One must certainly admire the effort put into keeping Delphine alive. (She’s for sale too – asking a cool Australian dollars $52M.)

Lydia Eva is the last representative of the iconic Yarmouth steam drifters – just back in steam after a lengthy restoration. On 27 June she celebrated her 80th birthday – John Oxley (who turned 80 in 2007) sent her a birthday email!

Quote from the Lydia Eva website … “Our thanks to all the volunteers, engineers and enthusiasts that made this possible.” Sounds familiar?