John Oxley Restoration

Latest Update August 2016

John Oxley is a 1927 Clyde built steamship being restored to operating condition by Sydney Heritage Fleet at Rozelle Bay in Sydney. The restoration is advanced with hull basically complete – Current work continues on replacement of her steel main deck while engineers work on machinery, piping, skin fittings and propeller shaft repairs.

John Oxley in 1970 steaming proudly into Sydney Harbour after delivery voyage from Brisbane.

We have resolved to recommence the traditional blogsheet below in conjunction with conventional social media www.facebook.com/johnoxleysteamship/ Read on!

DONATE: The project relies completely on some very special people who support this restoration through direct donation. We thank them for their continued generosity.

To donate to the project online buy.shf.org.au/donations but we would much rather make personal contact through a visit – Please call 02 9298 3888 to arrange.

VOLUNTEER: A big thankyou to our workforce. If you are able and wish to join in, please arrange to visit and meet our team.

We particularly need volunteers for the metal fabrication team on the ship plus engineering types for ‘down below’ in the engine room plus woodworkers for the shipwright team.

VISIT: Best days are Tuesday, Thursday and Saturday – Parking is tight so pre-arrange through 02 9298 3888. (Many of our people use easily reached public transport.)

GOODS & SERVICES: Not all can assist financially, but can you help with…

- Steel plate, angles and pipes

- Gas and welding consumables

- A replacement for our tired air compressor

- Nuts and bolts

- Air and electric tools – grinders, drills

- Drills, milling cutters, countersinks, taps, dies

Contact 02 9289 3888 to help!

RECENT WORK

NAVAL ARCHITECT: John Butler Designs (as project naval architect) advise that the weight of the finished John Oxley will be 706 tonnes. The planning team have systematically listed the weights and locations of all steelwork, timberwork, fittings and equipment onboard a finished John Oxley. The naval architect has transferred these to the 3D CAD stability model for our vintage steamship. From this, they have approved the design weights of forward hold and main hold tween decks plus sewerage tanks, gen sets and associated equipment. Decisions made by the naval architect here have allowed our fabricators to commence work in these spaces.

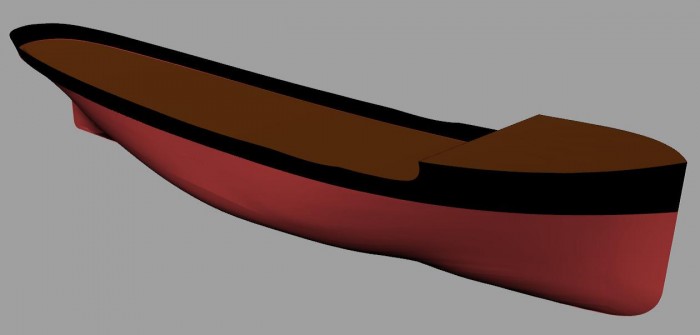

Rhino 3D CAD Render of John Oxley Hull Model

BOAT DECK: Rainwater from leaking through the boat deck causes much deterioration on ships like John Oxley, hence the hard decision was made to steel plate in this deck. Our naval architect advised that the extra weight was acceptable within the stability model and work commenced. The old wooden deck was removed and steel deck plates have now been fastened down and seal welded. A future composite wooden deck is planned, but for now the lower compartments are free of rain water and dry. A great result and thanks to our fabrication team here.

Tandem grinding of plate edges

Apprentice welding to produce watertight seal on boat deck plates

Work on side skirt plate boat deck

Volunteer drafter Glenn has prepared detailed plans of this deck which fix locations of the various fittings such as aft mast step, boat chocks and davits, vent cowls, life jacket boxes, Carley floats and railing positions. Shipwrights are preparing to install boat deck fittings.

Scaffolding system for boat deck

A substantial scaffolding system around the boat deck perimeter was designed and signed off by Scaffold Training Australia. It will be removed when the boat deck stanchions and railings are returned. Thanks to STA for their help here.

MAIN DECK: The fabrication team under Steve has returned to work on the starboard side main deck over the boiler space and are continuing new steel deck here. Old rusted and poorly repaired steel deck is first cut away and new steel installed. New steel plates here are supplied blasted and coated with Zinc primers. Some repairs to deck beams are needed, but these are minimal. This work takes place Tuesday to Saturday and we seriously need additional workers.

Fabricators Steve and Paul tidying up at end of day

WORKSHOP ACTIVITY: Shore workshop team are producing a range of projects for parts on John Oxley. Included are bunker and well deck hatches for later fitting.

Bosuns store hatch part finished

An interesting project has been the smithing of traditional brackets for hatch tarpaulin wedges. These were cut from plate and formed to shape under our old 50 tonne press. Holes were drilled and a dip in the galvanising tank followed.

Hatch tarpaulin brackets – forged and freshly galvanised

FORWARD HELD: Work has commenced in the forward hold on a permanent safe work platform and on the forward firepump stand. Work is well advanced here as shown.

Newbuild forward hold work platform beams bolted to original frames stbd side

Newbuild stand for diesel fire pump in forward hold

ENGINE ROOM: The work team under Garry Burns has achieved much this year. Highlights have included construction, galvanising and install of the bilge suction system in galvanised steel.

New bilge and freshwater mains

Auxiliary machinery is installed and is being connected to services. The engine room crane beam and runner is restored and back in place. Another milestone was the completion of engine room condenser system skin fittings. The original cast iron sea valves were condemned and RMS surveyors mandated modern sea valves as shown. Size is 10”

New condenser overboard discharge

Cleaning down the main engine has commenced and most auxiliary machinery will be running on compressed air by years end.

Bolton Paul circulating pump with Brisbane made Sargeants centrifugal pump

Aft feed pump and air pump Port side engine room

Work continues on cleaning the propeller shaft within the tunnel and cleaning and servicing the intermediate shaft bearings. Work has commenced on servicing/replacing oil lines to the sterntube.

Engine room bilges have also been painted – LP crankpit

Suitable WH&S is already being discussed as to how to enable the engine room to be opened to the public for tours.

ELECTRICAL: Design planning by Grant Campbell continues throughout the ship to provide for a complex array of requirements. The electricians already work on supplying construction wiring for lighting and power to the restoration. New cable trays are installed above in the engine room and a new cable tray system to run along the port side machinery spaces has commenced. This will carry power from the gen set to various parts of the ship.

OUR PEOPLE: Unfortunately our lead fabricator Onzie Ratu was on light duties due to health issues, but has found it necessary to retire from the project.

We therefore have an immediate need for additional metal fabricators. So if you are a fabricator and have time on your hands, we certainly need you.

The team also needs descalers, painters, general workers and potential ironworkers.

Please call 9298 3888 to arrange a visit.

Apprentice metal fabricator, Andrew Razzino has left the project to pursue other career opportunities. We are negotiating with our apprentice company for an immediate replacement.

Andy Munns

For John Oxley Project