John Oxley Restoration

Update December 2012

Last hull plate fit-up and Golden Rivet party

In 2002 a small team cut an access opening through a very thin hull plate in the main hold of John Oxley and started replacing steel work.

The only funding in our first year was a personal donation of $10,000 from Sydney Heritage Fleet board member Hugh Cross. However, there was a keen workforce with drive and lots of vision for a restored John Oxley as an important part of Australia’s national maritime heritage estate. Since this small start the project has grown and much has been achieved.

The Golden Rivet Party

10 years on, we have riveted the last hull plate below the main deck level. On 3rd November 2012 we celebrated this milestone event. The party was a great success and many of the current and past workforce attended. The food was excellent and thanks are due to the small team who worked so hard providing and preparing for this event.

The speeches were kept to a minimum, our volunteer workforce was thanked, in particular Barry Jones for his years of leadership and skill and also to Onzie Ratu, who as lead fabricator, has done so much to advance this project. We remembered some of our volunteers who sadly have passed away before seeing the project completed.

Our many sponsors were also thanked, for without their support, the restoration would not be as advanced.

For the main event the “Golden Rivet”, suitably engraved, was carried up to the furnace by long term volunteer Brian Hill. All on site then watched the John Oxley hull team as they “cooked” and drove the last rivets into the stem of John Oxley. It has been calculated that the team has driven over 25,000 rivets in the last 10 years!

The extraordinary progress is the direct result of the tireless and persistent work of the restoration team and the long term support of supporters and sponsors.

Volunteer, Hette Mollema, has for much of this time managed the project management software. He has also charted progress of the hull through regularly updated images that depicted hull replate progress and maintained the John Oxley website.

Hette’s concluding graphic shows the hull replating work now complete. With this work now accomplished, Hette has retired from his planning role and from the demanding physical work on the hull. We thank him for his input over many years and know he will continue his involvement in this project at a less physically demanding level.

Under the John Oxley‘s teak working deck is her actual steel plate deck. Decks are much more than for simply walking on. They are necessary for keeping the water out, but decks must also carry large structural loads when a ship goes to sea.

Unfortunately, steel plates under wooden decks are usually badly rusted and comprehensive repairs are necessary. John Oxley is no exception, so with the main hull work targets achieved, the team has already shifted to the main deck aft and will then work forward.

The teak overlay deck has been lifted to show badly rusted steel plate beneath. We knew about this problem, and the rather beautiful pilot’s saloon timber furniture and paneling has been removed to gain access and allow work to commence.

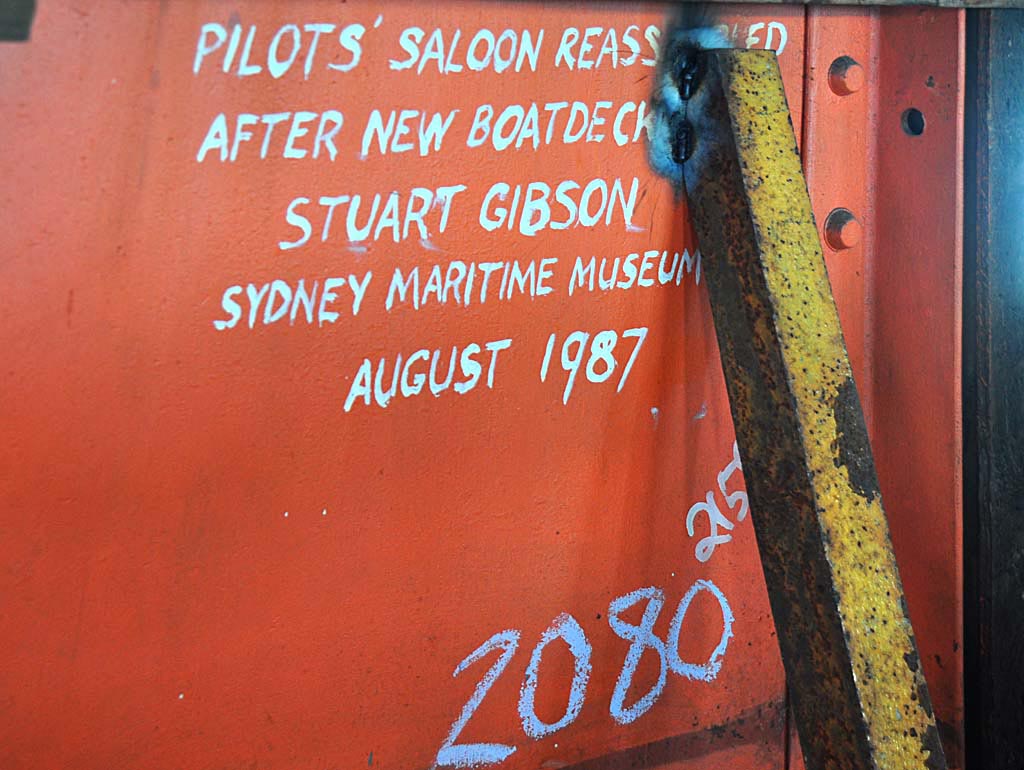

This part of the vessel has been visited before in the 1980’s when our restorers replaced the boat deck structure and deck planking.

Earlier work crews left written messages for future workers (us) to uncover and it is interesting to read the names of earlier generations of Heritage Fleet workers and read the record of work they have done.

Flush riveted plate seams in the superstructure

A special feature on John Oxley‘s superstructure are the flush riveted connections between all plates. This technology comes from 80 years ago so it is only a few visitors who have the earlier riveted ship background that have commented on this feature. Much of the repair here will focus on retaining as much of the original flush riveted seam length as possible, hence the decision to weld in a steel skirt rather than simply replace entire sections of the coaming plates.

This type of riveting demanded special skills from the team. They must drive each rivet into its pre-prepared countersunk hole, and at the same time be gathering any excess rivet steel to one side of the finished head and shearing it off through skillful use of the pneumatic riveting gun.

STA scaffolding partnership

The scaffolding is loaned and erected by Scaffold Training Australia who use the project and site for training and certification of scaffolders. After the scaffold is erected and signed off, it is available for John Oxley hull work.

For training purposes, scaffold towers are sometimes dismantled and then immediately re-erected as part of STA’s normal training work. We thank STA for their involvement and support in this area.

Engine room skylights

The teak skylights date from 1927 and are showing their age. Some of the teak is split and cracked and the varnish had failed many years ago. As is usual for Heritage Fleet projects, work happens when skilled people “adopt” a project and simply start work.

Members Bob Ellis and George were between projects and were shown these skylights stored in the yard. They quickly set up shop and started working on them. Teak is a wonderful timber as it can almost always be restored back to its original finish. It has been necessary to make a few graving pieces or inserts and glue them in.

Engineering

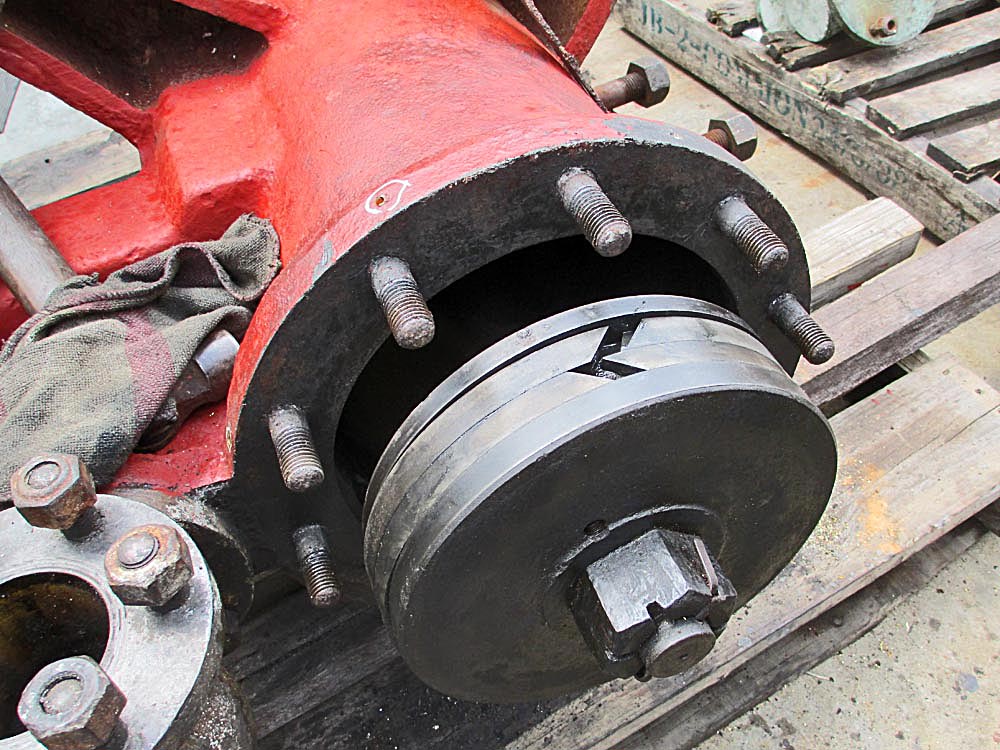

Air pump We had intended leaving the largee Dawson & Downie air pump in situ and working around this rather large pump. However, Ian and the team in the engine room had already moved quite a bit of heavy gear in and out of the engine room using our loaned 35 tonne shore based crane and felt it was possible to get the big pump ashore. This has now been done and volunteers are restoring the big pump to full operating condition.

The pump was made by Dawson & Downie. The company still exists and still makes duplex steam pumps for the marine and oil industries. Their 1927 air pump design has a single steam driving cylinder that drives twin pump cylinders through a rocker and links. The steam cylinder is of the shuttle valve style and has yet to be dismantled by the work crew.

Work reports from the 1980’s John Oxley engineers indicated the piston rings needed replacement, which is evident from the photo above that shows excessive ring-end gap plus the rings have lost their spring and will not seal. These will need to be turned from cast iron stock and can be made in our workshops.

Bilge and ballast piping

Steady progress on this part of the project continues. Original cast iron bulkhead valves have been overhauled. Timber patterns for replacement suction manifolds were made in our workshops and then cast by sponsor Wallbanks foundry. The castings have been machined and assembled by our volunteers. They are being bolted in place and are being used as station points for the piping systems.

The original bilge suction pipes were straight 6′ long cast iron pipes with lead pipes used for bends. They were badly corroded and their design can never comply with current codes.

New steel piping, bends and flanges have been donated. It involves a great amount of detailed work from the fabrication volunteers. Steel pipes must be cut and tack welded to bends and flanges. After final welding, the piping is sent out for galvanising. The result is gleaming zinc coated steel pipes bolted into the John Oxley.

Engine room paintout

Much of the engine room has recently been painted out in its final white colour. The paint is a two pack formulation with minimal Work Health & Safety issues. While the paint is expensive, it is very durable and we expect it to handle the knocks and bumps it will encounter during restoration of the machinery spaces.

The paint is applied using airless spray equipment. Though protective breathing gear is required, there is negligible over-spray with no dried paint dust to contaminate the engine room. The result looks superb.

Electricals

The old electrics were 110 volt DC supplied by the original Sisson steam engine driven dynamo set. This set cannot supply modern loads and cannot meet current Work Health & Safety requirements for protection of crew and visitors. Hence a 415 volt and 240 volt AC system is mandated for the navigation systems plus lighting, fridges and pumps.

Two generator sets have been donated and will be installed in a main hold enclosure. A third generator set, intended for emergency services, has also just been donated. They are in good condition but will need considerable cosmetic work.

Now the task is to obtain further sponsorship to refurbish these three generator sets. We are also seeking sponsorship of electrical equipment including

| • | Switchboards – main and sub boards |

| • | Heritage pattern switches for lighting |

| • | Power outlet/switches |

| • | Cable trays and fittings |

| • | Wiring for power and lighting |

Future work will include fire detection and other Work Health & Safety systems necessary under today’s codes.

Donation from Lady Scott to John Oxley

Rozelle Bay sees a lot of maritime industrial activity. One recent event was the breakup of the wooden hull of the old Sydney harbour ferry Lady Scott in the neighbouring yard of Australian Wharf & Bridge. She was built around 1910 and served on the harbour in many guises. While it was sad to see the demise of a piece of our history, the Heritage Fleet was pleased to receive the donation of some equipment from the old Lady.

Back in the 1980’s the John Oxley’s emergency steering wheel was stolen from its location down aft. It was a 10 spoke traditional wheel of 5′ (1.5 metres) in diameter. Its theft was a serious loss. The John Oxley team had recently repaired the vandalism done to the steering system from when the wheel was stolen and were about to start building a replacement wheel.

Our neighbour Paul Whitmarsh from Australian Wharf & Bridge offered the Lady Scott’s 10 spoke wheel to Sydney Heritage Fleet. It is a close match to the original. It will be fitted to the hand steering system on the aft deck.

The wheel was presented by Paul to the Heritage Fleet, and John Oxley, during the official speeches at the Kanangra’s 80th birthday party. We thank Paul and Australian Wharf & Bridge for their generous donation.

Project benefits

Volunteering

The project provides an opportunity for people to use existing skills and learn new ones. It is also an opportunity for forming friendships plus the social contact between like-minded people. The project is enjoyable to attend without the commercial pressure of the normal work environment. The volunteer workforce is physically engaged and mentally active. It is not your average “Men’s Shed”, as we also have many ladies volunteering on the project.

Youth training

We offer the metal industry the opportunity to sponsor apprentices to work on metal fabrication. Our apprentices in metal fabrication, and more recently a shipwright, have been vital to the restoration and there are now quite a few skilled tradies in the community who gained their work experience from our project.

We have also had a number of apprentices loaned or donated to the project by outside companies during light work periods. Another option is for apprentices to learn heritage trade skills if they volunteer on days off.

Economical use of funds and material utilisation

All purchases are well thought-out and nothing is wasted when materials are used. Even remnants of steel plate are used to make pipe flanges and for training our welders.

Preserving our nation’s maritime heritage

All this is in addition to the primary purpose – value to the community by preserving maritime treasures and keeping alive the skills needed to restore, operate and maintain our maritime heritage.

Equipment sought

Most of our equipment is ex-industry and was donated because it was commercially out of date or a workshop was closing. This is, in one way, fortunate as all of our work requirements are 1927 technology based and the donated machines feel quite at home.

The work team wish list includes:

| • | Plain drill press – #3 Morse taper |

| • | Horizontal borer – we are always needing to re-bore engine cylinders |

| • | Drills and bridge reamers for 5/8″, 3/4″ and 1″ rivet work |

| • | Nuts and bolts – all sizes – especially inch sizes |

| • | Air hoses – about 25 mm for mains and smaller sizes for air tools |

Seeking sponsorship for electric pumps

The pumps are needed sooner rather than later as we are fabricating the piping systems. These pumps are in addition to the steam pumps fitted to John Oxley. If you are able to supply or sponsor the pumps then please contact our office:

| • | 75 mm self-priming pumps for bilge service – 2 needed |

| • | 75 mm centrifugal pump for fire service |

| • | 75 mm centrifugal diesel powered for fire service |

| • | 32 mm centrifugal pump for deck wash |

To visit the project or help with materials or services, please contact our office on (02) 9298 3888 or drop in on the project and ask to see Tim Drinkwater or one of the John Oxley team members.