John Oxley Restoration

Update January 2010

We thank our volunteers, our small team of fabricators and our supporters for their enormous contribution so far. You are participating in the restoration of one of the last coastal steamers worldwide, and preserving a skill set that has almost been lost from the modern maritime and industrial landscape. Well done!

We thank our volunteers, our small team of fabricators and our supporters for their enormous contribution so far. You are participating in the restoration of one of the last coastal steamers worldwide, and preserving a skill set that has almost been lost from the modern maritime and industrial landscape. Well done!

For most, there has been no escape from the Global Financial Crisis. We go into 2010 with some limitations on our funding, but we are concentrating on those activities for which we already had materials on hand, or which did not involve major expenses.

SUPPORTING THE PROJECT

This restoration is a community based project. Our workforce is a mix of a couple of paid staff who support our many volunteers. Project direction and initiative is completely volunteer based.

Financial support from sponsors and donations of materials from business and industry is the only way we have of continuing this ambitious project.

We are always seeking additional support. To help, please make contact through the number below.

Funding – always the lifeblood of projects like the John Oxley restoration. Can you help in fund raising or for further information please contact us on (02) 9298 3888.

Support – are you in business or industry? Are you able to provide steel, tools, fastenings, or products and services useful to engineering projects?

New directions need new volunteers – as the project approaches refloat, we seek team members in the following areas –

| • | Publicity and promotions – seeking people to help with website, email, monthly reports |

| • | Events – planners and promoters – events for members, sponsors |

| • | Merchandisers – apparel, souvenirs and publications – shop counter and on-line |

Please contact us on (02) 9298 3888 or simply drop in on a weekday or Saturday and ask to talk to one of the team leaders.

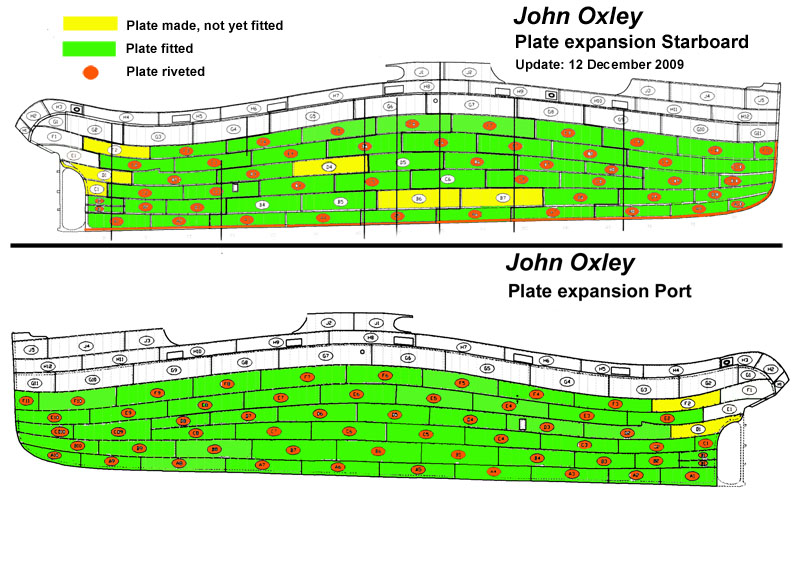

HULL

The progress on the hull plating is very visible to the observer and gives a real feeling of achievement. The work over the next few years will not be as visible, though no less important. We encourage all to take an interest and inspect that work so they know that progress is being made.

All plates below the waterline have been fabricated. The plates that were resting on the bilge docking blocks have been removed, replicated, fitted and riveted.

All plates below the waterline have been fabricated. The plates that were resting on the bilge docking blocks have been removed, replicated, fitted and riveted.

This activity required great care and skill as a significant weight of the hull rested on these blocks. Relief hull support was provided on either side of C5 and C6 starboard while each plate was removed and refitted in turn.

Plate D4 starboard will remain off for access into the engine room until just before the ship is re-floated. Safety mesh is installed to prevent workers from falling out and onto the dock.

Plate D4 starboard will remain off for access into the engine room until just before the ship is re-floated. Safety mesh is installed to prevent workers from falling out and onto the dock.

The bilge keel and the remaining plates will be fitted and riveted in the first quarter of 2010. Work also extends to the counter stern. Scaffolding has been sponsored and hull plates surveyed by NSW Maritime Authority. A schedule has been drawn up for the platework required. The plating here shows mainly localised wastage and most repairs will not require more than cropping and welding of inserts.

One of the complexities here will be the forming of plates into a bent flange or knuckle.

AFT DECK

Work has started on the aft deck. The teak deck planking up to the forward end of the aft peak tank has been removed. Ideas are floated if the planking can be reused for the deck. All fittings have been removed for restoration or replication. The steel tank top is in places in surprising good condition. The margin plates, bulwark and the top of the sheer strake plates need replacing. The fittings that need repair are being worked on in the workshop, like sheaves for the rudder chain and stanchions.

WORK ASHORE

The “new” milling machine has been improved with the fabricators erecting a heavy duty overhead lift frame, beam runner and ½ tonne chain block. This is already facilitating the work of fitting various milling heads.

The original 9″ cast iron sea valves were condemned. As special castings, they were not available “off the shelf” and it has been necessary to redesign these as weldments and obtain approvals from the NSW Maritime Authority. The fabrication team have now completed these – the image below shows some of the final fitting take place.

Another complex fabrication was required to replace the original cast iron aft end water box for the condenser. A building frame was put together to record with considerable accuracy the positions of all holes and flanges. A large welded ring and flange assembly was obtained, placed in the frame and new flanged connections made and fitted. Last task will be to grit blast and epoxy line the interior, this to resist the corrosive effects of sea water.

A by product of this process was the restoration of the condenser ends. These were heavily needle gunned to remove corrosion, grit blasted and then epoxy lined. Exteriors were needle gunned and painted with silver frost.

The workshop has also been remanufacturing new steering system fairleads. The originals show considerable rusting, no doubt due to many years of contact with sea water. They are manufactured from hull plate off cuts and represent considerable economic reuse of material.

Another project has been the repair of auxiliary pump platforms inside the engine room. Most pump platforms had over the years suffered from the effects of sea water drips. The workshop team again repaired the plates and riveted the structures back together again. All pump platforms are now riveted back into the ship.

Lastly, the emergency steering gear is of the screw type, manufactured by Mepo of Sunderland, birthplace of the James Craig, and incidentally of the same shape. It is located over the rudder and drives the rudder post directly. The workshop has again taken on the task of overhauling this important, but hopefully never needed piece of equipment. For more information go to the John Oxley steering system.

ENGINEERING

There have been demands from other parts of the Fleet and the engineers have been busy crewing the operational steamers as well as assisting in the annual refit of our steam tug Waratah. Work has included overhaul of her steering control shaft and a thorough overhaul to the steam duplex fire & bilge pump.

Work on John Oxley has included the overhaul of the sea water circulating pump. The shaft for this auxiliary is worn and is about to be replaced.

The image below shows the pump shaft being pressed out of the impeller. The impeller is in good condition and will be fitted to a new shaft.

We need to install the circulating pump, its engine and associated piping in order to install the new sea valve mentioned above. But before this can take place, the condenser will be jacked up about an inch to attend to rust between the condenser shell and its support bracket. The cast iron main engine exhaust pipe is currently being detached to allow this to happen.

A long term project has been the comprehensive overhaul of the two Weirs man feed pumps. This has been a “rainy day” project and gradual progress has been made over the years, Steam and pump cylinders have been rebored and honed. The steam piston and ring sets have been replaced. The bronze pump pistons were built up and new piston rings have been machined from Acetyl stock. We expect to fully reassemble these pumps early this year. They will be test run on compressed air and then broken down into sub-assemblies and returned to the ship.

VOLUNTEER WORKFORCE – WE NEED YOU!

| • | Sheet metal workers |

| • | Carpenters and shipwrights |

| • | Fitters / machinists / engineers |

| • | Fabricators and riveters |

| • | Iron workers |

| • | Painters |

| • | Electrical types |

| • | Machinery restorers |

Also we are always seeking people with practical skills to work with our existing workforce – new volunteers are surprised at how fast they become contributing members of a team. And remember, not all of our volunteers arrive with the above skills. Simple enthusiasm is far more important. There will be people there to show you what to do. Just start volunteering and see where it takes you!

WISH LIST

The project has a need for the following items…

| • | Horizontal borer – we bore out a lot of cylinders – not too large… |

| • | 3MT drill press |

| • | Any blacksmithing tools – need to ramp up our smithing facilities |

| • | Any riveting tools – especially old style |

| • | Air tools, power chisels, needle guns… |

| • | Ditto for electrical tools…drills, grinders… |

| • | Chain blocks – industrial rated |

| • | Any oxy-acetylene cutting equipment – new gauges and flashback arresters |

| • | A plasma cutter |

| • | Nuts and bolts, especially the larger Whitworth sizes |