John Oxley Restoration

Update January 2009

Introduction

The success of the restoration is now very visible in the progress of the hull plating. It is a tribute to all that have participated in the process through providing their volunteer efforts and those that have contributed with funds and materials. We thank them sincerely for their ongoing support and encourage others to do the same. You are participating in the restoration of one of a few coastal steamers in the world, and preserving a type of ship that once was plentiful in Australia and many other countries.

Supporting the project

The restoration is a community based project. Our workforce is a mix of a couple of paid staff who work alongside our many volunteers. We are grateful for the financial support from sponsors and we also are fortunate to obtain donations of materials from business and industry. The project is always looking for additional funds. They are the lifeline of projects like the John Oxley restoration. So, if you wish to become part of this restoration project please contact us on (02) 9298 3888

Also see the Wish List at the end of this restoration update.

At this stage, we have identified the need to expand project leadership, particularly in the areas of marketing and promotion. Anyone who can help with ideas in fund raising or for further information also please contact us on (02) 9298 3888.

Hull

Mid 2008, the team was working on the bow plating and stem. Riveting the stem and keel structures requires two riveters working on each 1 inch rivet from both sides simultaneously. After working up the stem, the team then concentrated on the keel, working aft from the forefoot.

Completing the structural A-strake was a major milestone. All the 1 inch rivets that fix the A-strake plates to the bar-keel and floors have now been riveted.

This task has been accomplished by to the hard work and dedication of the restoration team. Part of this team was our fourth year apprentice, Daniel, who was due to finish his time and leave in December 2008. Special thanks to the fabrication team who were able to complete the keel riveting phase of the project on the day before Daniel left.

- D-strake port side plate to be lifted in place

And, special thanks to Daniel who put so much into this project, and other Heritage Fleet projects.

The weight of the 600 ton ship has now been largely transferred back off B-strake onto the keel blocks by means of steel shoes and wedges.

The restoration of all of the structural floors and frames, and with most of the hull plating in place, has given the ship the stiffness of its original construction in 1927.

With the weight transferred to the keel blocks, work is progressing with the re-plating of the C and D-strakes that were obstructed by the bilge docking blocks. Each of the bilge docking blocks is carefully removed to give access to the plate for removal, plate duplication and riveting. The supports under the B-strake frames will stay in place to distribute the weight while this work is in progress.

Rudder

The top quarter of the rudder plate was rusted and considered below the required 0.900″ (22 mm.) thickness. This section has been removed, replaced and butt welded to the lower section. Riveting the new blade to the arm will take place early in 2009.

With most of the rudder components having been restored,independently inspected and approved, it is ready to be installed back into the ship. Installation will take place after the aft deck and rudder trunk have been restored.

Propeller

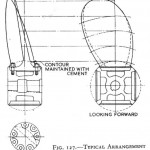

John Oxley‘s propeller is original and consists of a cast iron hub onto which are bolted four bronze blades. This type of propeller, while unusual to-day, was common for the time. The blades themselves were cast in Stones metal, a patent alloy, which is as strong as steel but is also corrosion resistant. Blades in this alloy are stronger, and can be produced in much thinner sections, resulting in higher efficiencies.

It was usual to cover the fastenings for the blades in a heavy coating of cement, which was fashioned by hand into a roughly spherical shape to minimise drag.

- Textbook example of builtup propeller - only one blade shown

The cement linings must be chiseled away to fully survey the blade fastenings. This difficult and dusty task is being undertaken, appropriately, by volunteer Dusty Miller. The fastenings will be inspected and verified using ultrasonic techniques when completed.

Engine room

The engine room is our next major challenge. Most of the engines and pumps have been restored in our shore workshop and need to be returned to the engine room before plating closes in this compartment.

Many of the auxiliary engine seats were removed to gain access for riveting the new hull plates. These seats and engines are to be returned to the engine room before it can be sealed off with new hull plating.

- Sisson auxiliary engibe restored - awaiting re-installatio

Access for riveting is made worse with the congestion of all this machinery crowding the space. Planning is critical to ensure it is done in a workable manner. It will be necessary to place the auxiliary engines, pumps and seats inside the engine room in temporary locations. They can finally be installed in their correct positions after the riveting.

Three of the more sizable components that need shore-side repair are the condenser ends. Repairs will include shot blasting and rebuilding with epoxy compounds, after which, these heavy components will be stored back inside the engine room. They are of a size that will require two complete strakes removed to manoeuvre them back into the hull.

Painting

All plates and structural parts are painted with a rust preventative coat and a sealant coat. The hull plates are zinc coated and have withstood the ravages of the weather well over the last few years. Hence the only painting visible externally are the rivet heads, giving a very clear outline of the rivet lines. Sealing the steel parts of the ship from the elements will have a major bearing on the life of the restoration process we are undertaking.

Workshop

The workload reduction of the structural elements and plating allows for more of its time to be spent on supporting the engineering effort.

The unusual image shows the engine room tread plate platform components. The entire structure was removed to the workshop, repaired piece by piece and prime coated. As storage space is limited, they are stored under the bow. When the hull riveting in the engine room is complete, this jigsaw puzzle will be reinstalled.

Repair and restoration of the rudder components, bilge pumping system, stokehold and engine room flooring has been undertaken.

The next few months will see the fabrication of two major hull valve boxes to replace those that cannot be repaired.

Electrical system

John Oxley was originally fitted with electric light in 1927. The system comprised a Sisson enclosed high-speed steam engine and Crompton 110 volt DC dynamo that supplied electricity to lighting, searchlight and to radio batteries. Over time, various power outlets, cabin fans and even a domestic fridge were added. Consequently, there were many complaints concerning serious overloads of the original generator set.

A group has been formed to undertake the design stage of a new electrical installation for John Oxley. A replicated 100 volt DC system will not satisfy to-days codes. Modern safety rules require provision of 415 and 240 volt AC, with many safety provisions, to power lighting, fire & bilge pumps, radios, fire detection systems, emergency systems and many other needs.

Under the leadership of David Logie, the group has commenced planning and will soon be active in recruiting labour and sourcing sponsorships and assistance from industry.

Wish List

The project has a need for the following items…

The project has a need for the following items…

| • | Horizontal borer – not too large… |

| • | 3MT drill press |

| • | Radial arm saw (for the chippies) |

| • | Any blacksmithing tools |

| • | Any riveting tools |

| • | Air tools, power chisels, needle guns… |

| • | Ditto for electrical tools…drills, grinders… |

| • | Chain blocks – industrial rated |

| • | Any oxy acetylene equipment |

| • | A plasma cutter |

| • | Nuts and bolts, especially the larger sizes |

| • | Used or new sheet roofing material |

AND – are you retired? Seeking something to do? Seeking useful work? Want to preserve our heritage?

The project is looking for extra volunteers…

| • | Sheetmetal workers |

| • | Carpenters and shipwrights |

| • | Fitters / machinists / engineers |

| • | Fabricators and potential riveters |

| • | Ironworkers |

| • | Painters |

| • | Machinery restorers |

We are always seeking people with practical skills to work with our existing workforce. New volunteers are surprised at how fast they can learn and become valued members of the team.