John Oxley Restoration

Update January 2011

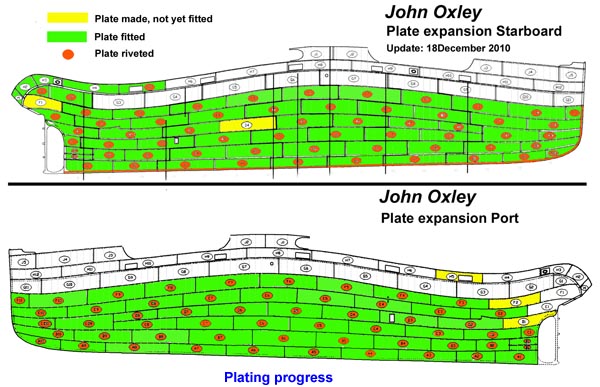

Hull

Stern

The work over the last 6 months has concentrated on the starboard stern area. The framing and plating here is complex and has taken more time than was planned. Some of the deck plating was in surprisingly good condition with the main rust areas in the margin plates and to the frame work beneath the concrete lined gutter. Inserts have been made for the rusted frames with about 65% of the original structure being retained.

Also located at the extreme stern beneath the deck is the void space aft. This small space is completely closed in and serves no useful purpose other than to form and support the stern counter. The framing changes in this space and becomes cant frames, which radiate out from the aft peak bulkhead. This space had been completely sealed since 1927 and it was interesting to see how the original shipbuilders had carried out their work.

Another complex structure in the void space is the rudder stock trunking. This is a heavy steel tapered tube, which was badly rusted. A short piece of heavy steel piling was given to the project by our neighbours Australian Wharf and Bridge and the required taper produced with oxy and arc welders.

Bulwarks aft

The complexity of the aft bulwarks was mentioned in the previous John Oxley project update and this has certainly been borne out in the fabrication process. The lessons learnt while working on the Starboard side will be applied to the Port side restoration, that was left in place till the starboard side was completed. It provides a reference point in order to keep the original shape.

The starboard bulwark plates H1 to H5 are now in place with H5 fully riveted. They are fully fitted with scuppers fairleads and coaming.

Most of the steering chain sheaves have now been reconditioned. The sheaves themselves were generally in good condition but their steel housings needed replacement. The bearing bushes and pins were badly worn and had to be replaced.

Stern frame

The stern frame is in good condition as were the stem and bar keel. This is a built up forging with pre-forged sub-components fire welded together back in 1927. The original hull draft marking were found beneath layers of rust and paint. They were chiseled into the steel of the sternpost. Interestingly, while all the numbers show feet in Roman numerals, the draft of 14 feet is shown as “XIV” on the starboard side but as “14” on the port side. We may retain this oddity on the final marking.

Without the scaffolding, and its constant adjustment to suit the needs of the plating team, the work on the stern would have been very onerous. We thank Kell & Rigby for their valuable contribution. We also thank our long-term rigger/scaffolder for his tireless efforts in setting up what is an ambitious scaffold.

Machinery

All the auxiliary engines and pumps have now been reconditioned and test run on compressed air. The Weir main feed pump set is shown below and can be seen running on compressed air following a comprehensive overhaul. One pump works as the duty main feed pump, with the second pump on standby. Of special note is the Weir shuttle valve gear that was responsible for the low steam consumption of these pumps.

The Weir feed pump set was once the predominant reciprocating pump found on board steamships and in land based steam plants. The company is still in existence, but no longer manufactures this type of pump.

The Dawson and Downie steam ballast pump was installed to move freshwater from one peak tank to another. It is the largest reciprocating steam pump in the Sydney Heritage Fleet collection. It is also cross connected to the condenser and can be used as backup circulating pump if the main circ pump fails. Following its assembly, the pump has been test run on compressed air.

The Dawson & Downie firm still manufactures duplex steam reciprocating pumps for industry and oil mining applications, but their current product does not look like John Oxley’s 1927 version. The firm was still able to supply general arrangement drawings! See their website

Another milestone was the return of the aft condenser water box following grit blasting and painting by sponsors Australian Winch. This large component replaces the original cast iron water box that was badly wasted and cracked. The old water box was put in a fabrication frame and temporary flanges set up to record every detail. The new steel weldment was then made on this frame so that the new water box matches all piping connections exactly.

The main injection valve (or condenser cooling water inlet sea valve) has yet to be fitted to the hull , to achieve this accurate fit-up, the condenser piping was erected ashore and a setup jig made so that the exact location of the main injection valve can be marked on the hull.

There is some discussion on the timing of putting components, engines and pumps back into the engine room. Doing it now will entail covering these engines against debris from the overhead work on the deck. It maybe easier to do it now while there is a hull opening at plate D4 starboard.

Planning

Planning is starting on the tasks needed to float the ship in the next few years. There was a concern that the condition of or 1913 ferry Kanangra’s hull would require her to be placed on the Sea Heritage Dock much sooner than was planned. The surveyors report on the condition of the hull of the Kanangra has allayed some of these fears and we are able to keep to our original John Oxley task plan critical path.

Future tasks for 2011 will comprise a compartment by compartment check for outstanding work and safety fit-out.

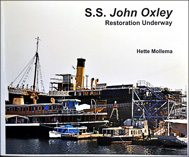

Book release

A Book on the restoration of the John Oxley is now available via an on-line publisher. If you have had any association with the ship then this book is a must. Please read the summary and review.

A Book on the restoration of the John Oxley is now available via an on-line publisher. If you have had any association with the ship then this book is a must. Please read the summary and review.

Volunteers sought

As the project approaches refloat, there is the need to accelerate progress. The work will become more complex, more work teams will be needed and more materials must be sourced.

On site we need:

| • | Carpenters and shipwrights – on deck |

| • | Fitters / machinists / engineers / machinery restorers |

| • | Fabricators / riveters / iron workers – in workshop and on board |

| • | Painters – everywhere… |

Offsite – the project also needs people that are good at:

| • | Publicity / promotions – volunteers to help with website, email, reports |

| • | Events – planners and promoters – events for members, sponsors |

| • | Merchandising – apparel, souvenirs and publications – shop counter and on-line |

| • | Fundraising |

And then we need support from business or industry. Are you able to provide steel, tools, fastenings, or products and services to the project?

Some of industry supplied materials:

To visit the project or help with materials or services, contact Jon Simpson on (02) 9298 3888 or drop in on the project and ask to see Tim Drinkwater or one of the John Oxley team.