John Oxley Restoration

Update December 2006

Structural work under the boilers completed

One look at the structure beneath the boilers was enough to alarm most people. We had over 60 tons of boilers and a heavy superstructure supported on a badly rusted structure. It was clear there was much to be done here, and that it would be an engineering challenge to hold up 60 odd tons of boilers and many more tons of hull and superstructure while severely wasted floors and frames were replaced. It was known that each massive boiler was gradually settling down into the vessel. To prevent this, steel angles were wedged into place under each boiler and welded into place.

First task was to raise each boiler some 20 mm. This was needed to remove their weight from the hull while repairs underneath could commence. A grid constructed of heavy steel sections was used to support the boilers to the dock. Each boiler was raised in turn by our donated 50 ton Enerpac jack and then lowered onto packers. See also How-it-was-done.

With the boilers now supported clear of the weakened hull, work commenced on the floors beneath. Each floor was cut away from the hull and then taken ashore for replication. The new structural members were returned to the ship and bolted in place, with the riveters coming along later to finish the job.

Final work in this compartment was to replace the intercostals between the floors and recondition the boiler stools.

With all of this work now complete, both boilers have just been lowered back down to just rest on their stools. Most of their weight is still be held off the hull until hull plating here is completed.

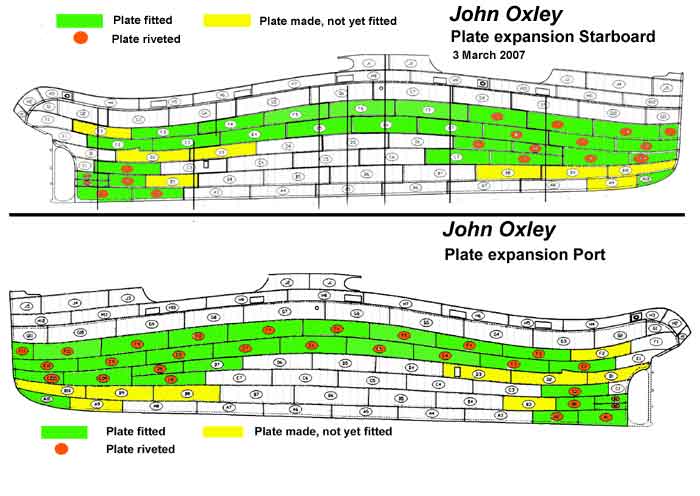

Hull plating progress

Almost all the accessible plates, about 70 in total, have been replicated and most are fitted to the hull. About 45 plates are fully riveted. See below the marked-up plating expansion image.

Restoration of Pilot’s accommodation

This compartment with it’s timber panelling and beautiful Queensland Rosewood furnishings is one of the special features on board John Oxley.

Unfortunately we already knew that this compartment had rust problems underneath the concrete deck lining. First task was to carefully dismantle, mark and store the entire contents of this compartment. This task was undertaken by a number of volunteers; with shipwright volunteer Tony Blakelock taking on the majority of the clearing out and storage work.

Next task was to remove the concrete deck lining and cart it away. It was immediately apparent that the riveted steel deck underneath was in worse condition than was believed. With the concrete removed, the workforce had to protect themselves from falling through open rust holes.

Though it is a lot of work, but we always try to descale the rusted rivet heads before oxy cutting. This takes time, but if not done, costs dearly in gas is consumption, and the cutters experience many more uncomfortable blowbacks.

- Before - gaping rust holes in the pilot flat and rusted structure

- During - Onsie removing rivets with torch

- After - new plate riveted into place, ready for painting

The process was to remove the rivets without harming the rusted plates and angles. The plate was lifted out with chain blocks and taken ashore, where the workshop team replicated the external shape exactly. Rivet holes were drilled in the new plate by laying the old plate on top of the new plate as a drill guide.

The new plate was lifted back into place and bolted up. Final preparatory work involved careful aligning of holes and reaming them to final size before riveting.

Our workforce had made the promise that the compartment would be completed before Christmas!

As their deadline approached, volunteers came in additional days and on the Saturday before Christmas Eve, some 60 rivets remained. A concerted push saw these last rivets completed just after lunch. A tired but very satisfied workforce stopped work, tidied up and went home to enjoy their Christmas.

Heritage Commission grant and refurbishment of boilers

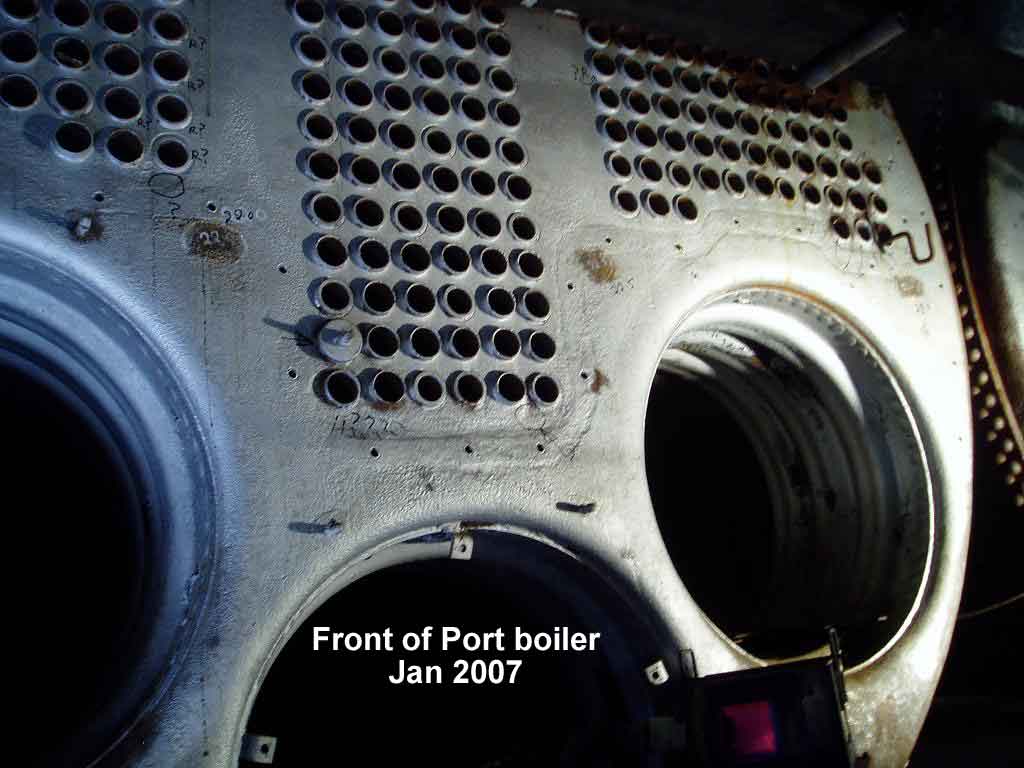

A highlight of 2006 was the “Kickstart Grant” for the boilers on John Oxley. While we were excited to receive this grant, the flow-on cash support from the Sydney Heritage Fleet membership was equally heartening. Up to the end of 2006, both boilers were needlegunned and a grid established for ultrasonic thickness testing.

A highlight of 2006 was the “Kickstart Grant” for the boilers on John Oxley. While we were excited to receive this grant, the flow-on cash support from the Sydney Heritage Fleet membership was equally heartening. Up to the end of 2006, both boilers were needlegunned and a grid established for ultrasonic thickness testing.

This testing has commenced, with positive results so far.

A boiler inspector has also been appointed and recommendations on future work to return the boilers to steaming condition have been made.

We were pleased to find the original Queensland Harbours & Marine Board work reports on the boilers and engines dating from the 1960’s. These make interesting reading, and reveal that the boilers were extensively retubed during this time. With this in mind, it seems likely that far fewer boiler tubes will need replacing than previously thought.

Work planned for 2007 will be more detailed inspection of known problem areas, removal of about 50 suspect boiler tubes and then the application of coats of heat resisting paint over the boiler exterior drums.

Removal of engine room machinery while hull plates are removed

Much of the machinery in John Oxley‘s engine room has to be shifted away from the hull so that the hull repair teams can get up close and personal to the hull itself.

While hull plates are off, there is the opportunityto remove this machinery to the shipyard for overhaul.

So far, the Howden forced draft engine, fan and ducting have been removed. These are by far the largest auxiliaries and it is essential that they are restored and returned before the engine room plating is replaced.

Other auxiliary machinery removed include the Weir main feed pumps, both of which need reboring. The big Dawson and Downie ballast pump has been removed, its pump end was acid pickled to remove heavy corrosion deposits and a start made on refurbishing the steam cylinders.

The Dawson & Downie fire and bilge pump had already been removed some years ago and is now restored waiting for installation. The oil fuel pumps have also been overhauled and are in storage.

Rudder removal and research

Late in 2006, the preparatory work needed before the rudder stock and rudder could be removed had been completed. Heavy components such as the emergency steering crosshead and tiller arm had been dismantled using specially built heavy pullers and large hydraulic jacks.

One of the special enjoyments of volunteering in the Heritage Fleet, is the chance to play with some very special “toys”. The crane used to remove the boom derrick, the Clarke Chapman deck winch and all the rudder components was a 60 tonne all terrain type. Only this type of crane had the all wheel steering system necessary to get in and then out of our smallish site.

With the lifts planned and risk assessments in place, the crane commenced and made short work of the derrick boom and the deck winch. Removal of the rudder and stock were more difficult and ingenuity plus tackle were needed to get the rudder off the ship and onto the dock.

Current work on these parts is the analysis of the steels used in components, determining welding procedures and obtaining approvals from our survey authority.

Bilge piping system

Much of the cast iron bilge system is badly corroded and will need replacement. Patterns for replica bilge system manifold valves have been made by Ken Bryant, our volunteer patternmaker, and castings donated by our sponsor Wallbanks Foundry. See also How-it-is-done

These castings are currently being machined with our old but heavy Cincinnati mill purchased to do this work. This mill, although of a decent size itself, is only just big enough to squeeze these castings in under the cutter.

When the bilge manifold valves are complete, they can be installed and a start made on manufacture of new bilge suction pipes.

Volunteers and volunteering

While many readers of this page are not local residents, some might be. We are always seeking volunteers – our project enjoys the solid work of so many volunteers and we are very grateful for their valued support.

Please remember that our volunteers come from all walks of life – our workforce consists of both the young and not so young – we have men and an increasing number of women on site. We also have professors and publicans, managers, businessmen, pharmacists, solicitors, teachers – all are united by the drive to progress work on the John Oxley.

Some of our workforce bring valued ship repair or similar skills to the project – many others turn up and quickly learn skills that make them very useful.

Those who wish to join in can contact our office on 9298 3888 and ask to join in on our next tour group and induction. Alternatively, turn up at the Rozelle Bay shipyard on either Tuesday, Thursday or on Saturday and ask to speak with one of the volunteer leaders.

Supporting the project

We are very grateful for the sponsorship provided to the project by some very special people. Without their generosity, the project would not be moving ahead so successfully.

The project is always seeking more support – the more we get, the faster the project runs.

Many companies and businesses assist by donating or discounting their services, or by supplying materials and funding. This restoration with it’s non-profit status and hard working workforce certainly inspires others to get involved with the project – if businesses or individuals feel they are in a position to help, please make contact through 9298 3888.