Riveting

The John Oxley is a fully riveted ship. Rivets were used to join iron or steel components together in ship building and other construction works before the use of welding in shipbuilding during the Second World War.

The John Oxley is a fully riveted ship. Rivets were used to join iron or steel components together in ship building and other construction works before the use of welding in shipbuilding during the Second World War.

Even so, riveting continued to be used in shipbuilding till the end of the 1950s. It was the only reliable way, from the dawn of the Industrial Revolution, to join structural components together. The Sydney Harbour Bridge was entirely built with rivets.

It is no surprise then that the early ships like the Great Britain, by Brunel, were constructed with rivets. With rivets between 3 to 5 times their diameter apart, air and watertight seals could be made with overlapping plates. The boilers of steam engines were also made with rivets.

The rivet is “cooked” till it is light yellow. Then it is inserted into the hole and pressure is applied to deform, or flow, the metal into the available space. A pneumatic hammer, or a hydraulic ram in a steel “G” clamp, is used to apply the pressure.

The rivet is “cooked” till it is light yellow. Then it is inserted into the hole and pressure is applied to deform, or flow, the metal into the available space. A pneumatic hammer, or a hydraulic ram in a steel “G” clamp, is used to apply the pressure.

The tools are fitted with adaptors, snaps or dollies, that are hollowed out in the shape of the final rivet head. The rivets are heated to approximately 1000 degrees C to make them flow better than when they are cold. Much like the smith shaping a horseshoe in his furnace. The temperature of the rivet is judged by eye. They need to be light yellow, without any dark occlusions in the body.

The hot rivets are handled with long tongs that are regularly cooled in water. The diameter of the rivet shank is a little less than the hole diameter, i.e. 3/4” rivet is used for a 13/16” hole. The shank length needs to have enough material to fill the hole and to form the head when compressed. The “rule of thumb” for the shank length of a 3/4” rivet is the combined plate thickness to be joined plus about 1”. Extra length may be needed for the head or countersink. If the holes do not perfectly line up, then a little extra length may be required after reaming. Always do a dummy run to get it right for a certain combination.

A small propane fuelled furnace with forced air is used to heat the rivets.

A small propane fuelled furnace with forced air is used to heat the rivets.

Rivets on the external side of the hull, where they are in contact with the water, are countersunk to reduce drag and to improve water tightness. The 1 inch countersunk bar keel rivet from 1927 is pictured to show how well it has been preserved despite being immersed in salt water for most of its life.

The type of steel used for the rivets today is a fairly malleable, or ductile, steel that can withstand serious deformation without cracking or serious weakening.

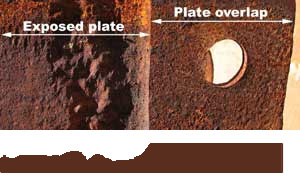

The distance between rivets is about 4 to 5 times the diameter of the shank. Plates joined this way have proven to be water and airtight. This is highlighted when the plates of the John Oxley are removed. The exposed part of the plate has corroded, but the seams, where the plates overlapped, are in almost pristine condition, as when it was build in 1927. It is a great tribute to the workmanship of the Clyde shipyard.

The rivet spacing is a compromise between the sheer strength of the rivet, friction between the plates at the overlap and the plate’s resistance to tearing. Where absolutely no leakage is permitted and the static load is similar to the dynamic load, the rivets are placed 2 to 3 times the shank diameter apart. This may be seen on oil tanks ashore.

In September 2006 a test was undertaken to confirm our riveting technique of the 1 inch keelbar rivets. The keelbar runs the length of the ship, joining the Port and Starboard A-strake. The test sample had similar bar dimensions of 40 mm (1.5 inch) with a 10 mm plate on either side. The sample was cut in half to examine the result.

In September 2006 a test was undertaken to confirm our riveting technique of the 1 inch keelbar rivets. The keelbar runs the length of the ship, joining the Port and Starboard A-strake. The test sample had similar bar dimensions of 40 mm (1.5 inch) with a 10 mm plate on either side. The sample was cut in half to examine the result.

The result was successful, note the very close fit on the head. The rivet filled the available space.

In general, the parts to be riveted will be assembled and tightly bolted together every other hole. Alternative holes are riveted before undoing the nuts and bolts. On long sections, rivet from the centre of the piece out to the edge on the first pass and do the same when the bolts and nuts are removed.