Restoration

After more than 70 years, the effects of salt water and air have corroded a number of the structural components of the ship. The immediate task is to replace the rusted floors and frames, and then replace the hull plates where required. As with all Sydney Heritage Fleet restoration projects, we do this work with a team of volunteers.

This type of work involves removal of the old sections by oxy cutting the original rivets. The section is removed from the ship with chain blocks and taken to our workshop for replication. The new replacement is then returned to the ship and bolted in place. Final work involves riveting-in the new section.

Planning

Stage-1, restoring to float the John Oxley, has been planned using IT Gantt charts. All tasks and their dependencies are taken into account. This plan ensures that the tasks are done in the correct order and that all are completed before the end of stage-1. The admin team is comprised of volunteer fabricators, engineers and shipwright all who have a keen interest in this old ship and its future.

Hull

Hull

Many floors and frames (or ribs) lower down in the hull had extensive corrosion and were replaced. Each of the floors that need replacement are removed from the ship and replicated in the on-shore workshop using the same techniques that were employed in building the ship in 1927.

Most of the hull plates, in particular at the water and air interface, need replacement. Each plate is removed in turn and used as a template for its dimensions and the drilling of the holes to match its neighbouring plate and frames. It is then shaped, using a hydraulic ram fixture to match the shape of the hull where it will be placed. Some more difficult shapes are hot-spotted, a process usung gas torch and hose to shrink a 3 dimensional shape into a plate (These methods are still used in modern shipyeards today). Once placed back onto the hull, it is tack-bolted into place for riveting. Steel wedges are placed in the gaps where the plates meet to provide a watertight seal.

Riveting teams follow and restoration of the hull today is practically complete. The riveting teams are no longer found in industry today – Our people have needed to relearn the old skills of rivet cooking, holding up and riveting. Final sealing is carried out by caulking teams, who use air chisels to drive the plate lap edges together to form a full watertight seal.

Engineering

Our volunteer engineers have overhauled all sea valves, the steam bilge pump followed by the rudder and propeller shafting. An initial early task was the careful and expensive contractor level task of asbestos removal.

Fortunately, most of the steam and exhaust valves were in good condition. Sea valves have been repaired or replaced. Bilge manifolds were also replaced as castings or weldments. Our late volunteer patternmaker Ken has produced the many patterns needed to cast new versions of old components in cast iron, bronze and brass.

The engineering team under CE Gary has reinstalled all engine room machinery and has advanced the installation of steam, steam exhaust , fresh water, seawater, bilge and fire systems. Port boiler tubes have been removed and the boiler inspected. Current work on refloat has required a focus on hull engineering and current boiler room work is on hold.

Electrical

Temporary construction wiring and switchboards have been provided to the hold, forward hold, stokehold and engine room for the restoration process.

The original electrical wiring network was made of lead sheathing over cotton and India rubber insulation. This type of wiring is no longer available and it does not last. In her last years of service, John Oxley was plagued with many short circuits and other problems caused by perished rubber insulation. Our Survey authority does no permit use of the original 119 volt DC wiring systems, hence a change to 240/415 volt AC is required.

Detailed planning of the electrical wiring for refloat is in train. Switchboards are almost complete and the shorepower isolation transformer is on board. We will use a modern code wire installed on new cable trays.

The volunteer electricians are gathering electrical wiring and equipment, rebuilding it and putting into store, ready for the day when they can install it and wire the ship.

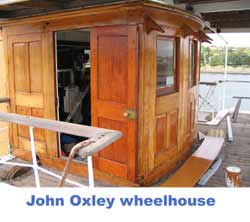

Shipwright

The ship was fitted with teak decking and internal wood panelling. Much of this is in need of repair and re-finishing. The wheelhouse, in particular, is a fine example of a ship bridge of the period.

100% of the original teak main and upper decks was removed to gain access to the steel structures beneath. Steel plate decks over the machinery spaces were replaced and the decision was made to continue steel plate decks over other parts of the hull to best prevent future damage through water leaks. Future timber decks will be subject to fundraising efforts.

Meanwhile cabin teams have been restoring the wheelhouse, Master’s cabin, chartroom, pilot’s mess and engineer’s cabins. A start has been made on the officer’s mess. These are vital future display spaces and great effort is made to ensure authentic appearances.