Caulking Plate Edges

On a ship with riveted plates, water can penetrate the through the plate edges. The exposed edge of the outside plate is called the caulking edge. Caulking on steel vessels involves forcing an edge of the outside plate tight against the inside plate sealing the lap joint. This is accomplished with an air powered chipping hammer and a caulking tool that wedges the inboard part of the caulking edge toward the inside plate.

On a ship with riveted plates, water can penetrate the through the plate edges. The exposed edge of the outside plate is called the caulking edge. Caulking on steel vessels involves forcing an edge of the outside plate tight against the inside plate sealing the lap joint. This is accomplished with an air powered chipping hammer and a caulking tool that wedges the inboard part of the caulking edge toward the inside plate.

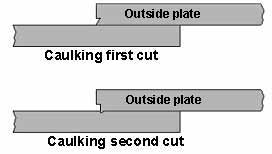

The first pass with the tool cuts a wedge shaped groove about 1/8″ to 1/4″ wide. The high side of the wedge shape is against the inside plate. On the second pass, the tool is turned 180 degrees and used to force the wedge shape down flat and tight against the inside plate. The finished caulking edge has a slight step on its inboard edge towards the inside plate.

Repairs to caulking edges of riveted plates are also done from the outside of the plate. If a gap greater than l/16″ exists between the two plates, the edge can be heated and brought tight by means of a flattening hammer. This double-headed hammer has a round end to be hit with a sledgehammer and a square end that rests against the plate.

Repairs to caulking edges of riveted plates are also done from the outside of the plate. If a gap greater than l/16″ exists between the two plates, the edge can be heated and brought tight by means of a flattening hammer. This double-headed hammer has a round end to be hit with a sledgehammer and a square end that rests against the plate.

After the plate is heated enough to allow its edge to be hammered back in place, one person holds the flattening hammer against the plate and another hits the round end with a sledge hammer. Finally the edge is recaulked as above.

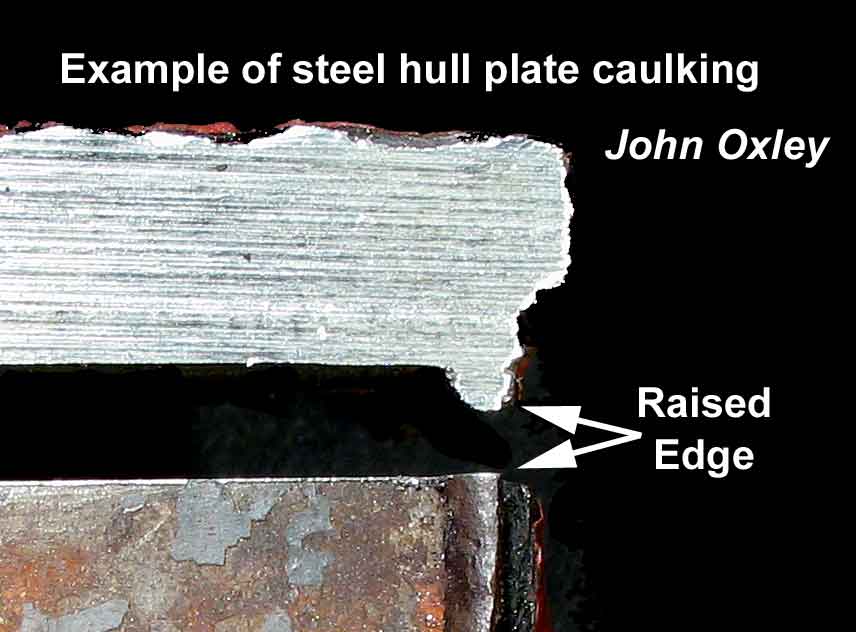

This is an image of the edge of a steel plate from the John Oxley. It was recovered from a plate that needed to be replaced. The raised edge is about 2 mm high, and on the limit of what is acceptable. The further the edge is away from the rivet line, the more likely it is that the edge of the plate will bend when caulking the plate edge. Ideally, the plate edge should be about one rivet thickness away from the edge of the rivet hole.