Bending Hull Plates Into Complex Shapes

Complex curves have been applied to new plates based on the following theory:

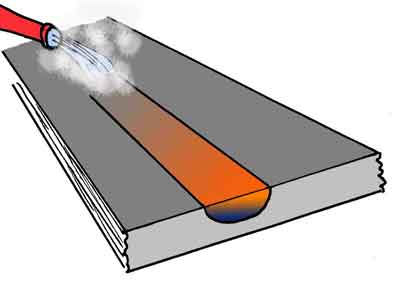

If heat is applied to an area that is constraint by cold metal, then the expansion of the metal will result in compression, evidenced by a slight bulging of the heated area.

Rapid cooling of the heated area will freeze the expanded or stressed area and produce a contraction in the metal. Should you want to curve a flat plate, then you heat the plate to about half its thickness till it it starts to show a reddish colour. Flowing cooling water about 2inches (5cm) behind the heating torch will contract the metal in that surface of the plate.

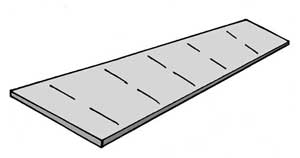

Trial and error will determine the interval between the number of lines required for the amount of curvature. As a guide 10 lines will induce a deviation of approximately 6 inches, 15 cm, from the horizontal in a 5 metre by 1.5 metre plate of 10 mm thick. This is metallurgical abuse and is only tolerable with steel of low carbon equivalence.