Bending Hull Frames

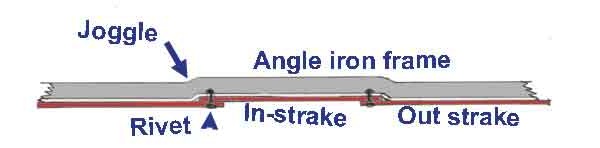

The entire lower half of the hull is curved. In the builder’s shipyard the frames were heated in a furnace and curved according to the ship’s design. Not only are the frames curved, they are also joggled. Joggling means that the frame follows the inside surface of the hull plates that are alternatively in and out side strakes.

The entire lower half of the hull is curved. In the builder’s shipyard the frames were heated in a furnace and curved according to the ship’s design. Not only are the frames curved, they are also joggled. Joggling means that the frame follows the inside surface of the hull plates that are alternatively in and out side strakes.

Unfortunately we do not have a large furnace and have developed an alternative method that delivers good results. First the frame is bent to follow the curve of the hull. Then the joggle is made. The original frame is used as a template for all operations, including drilling the holes to match those in the plates.

Unfortunately we do not have a large furnace and have developed an alternative method that delivers good results. First the frame is bent to follow the curve of the hull. Then the joggle is made. The original frame is used as a template for all operations, including drilling the holes to match those in the plates.

The original frame is laid on the heavy steel worktable, the tabletop is a 2 inch (50mm) steel plate.

The metal for the replacement is cut to have about an extra 1.5 m (5 feet) as leverage when applying bending pressure. The outline of the original frame is drawn onto the tabletop.

Steel stops, 1 inch thick, are welded on one side only to the tabletop. Welding the stops on one side only helps with their removal at the end of the operation. The angle iron is welded to the tabletop at one end and secured with a stout G clamp as additional security.

A chain hoist wrench is attached to the other end of the angle iron using a temporary welded-on eyelet. One or more angle irons are bolted across the frame to reduce warping of the frame. The frame angle iron is heated to cherry-red at about 2 inch intervals, starting at the secured end. The other end of the frame is pulled over by the chain hoist and the frame will bend at the heated section. In effect, it will thicken there. This process is repeated many times till the frame conforms to the shape of the stops welded on the table. When the bending is completed, further heat treatment may be required to reduce warping. When the bending is completed, further heat treatment may be required to reduce warping further.

A chain hoist wrench is attached to the other end of the angle iron using a temporary welded-on eyelet. One or more angle irons are bolted across the frame to reduce warping of the frame. The frame angle iron is heated to cherry-red at about 2 inch intervals, starting at the secured end. The other end of the frame is pulled over by the chain hoist and the frame will bend at the heated section. In effect, it will thicken there. This process is repeated many times till the frame conforms to the shape of the stops welded on the table. When the bending is completed, further heat treatment may be required to reduce warping. When the bending is completed, further heat treatment may be required to reduce warping further.

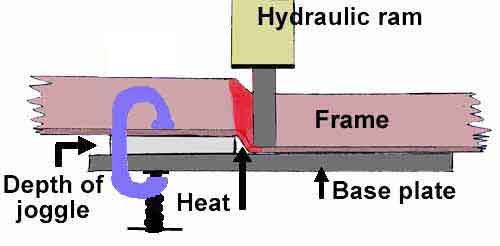

To joggle the frame, a manually pumped hydraulic press is used. With the location of the joggle marked on the frame, the area to be joggled is heated till cherry-red. A packing plate of the same thickness as the joggle depth supports the “in” part.

The ram is pumped till the “out” section has reached the press base plate and kept for about 30 seconds. See diagram below.